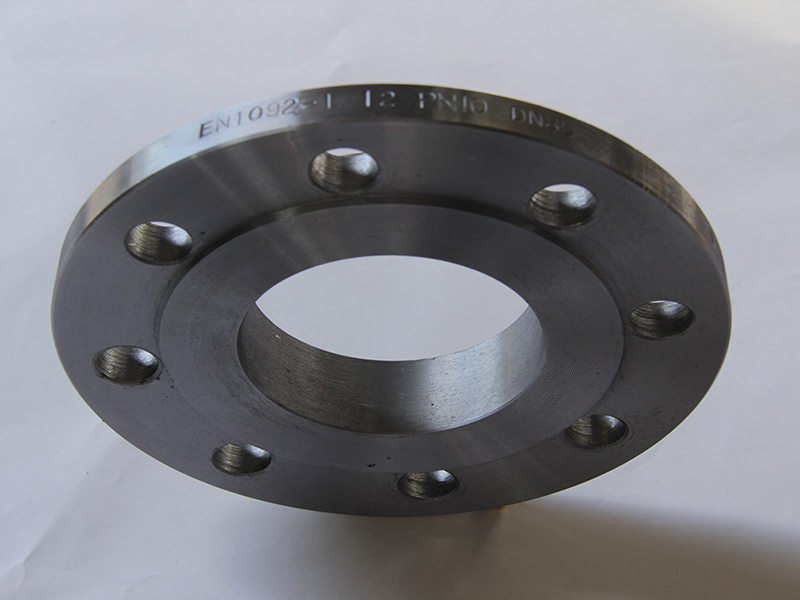

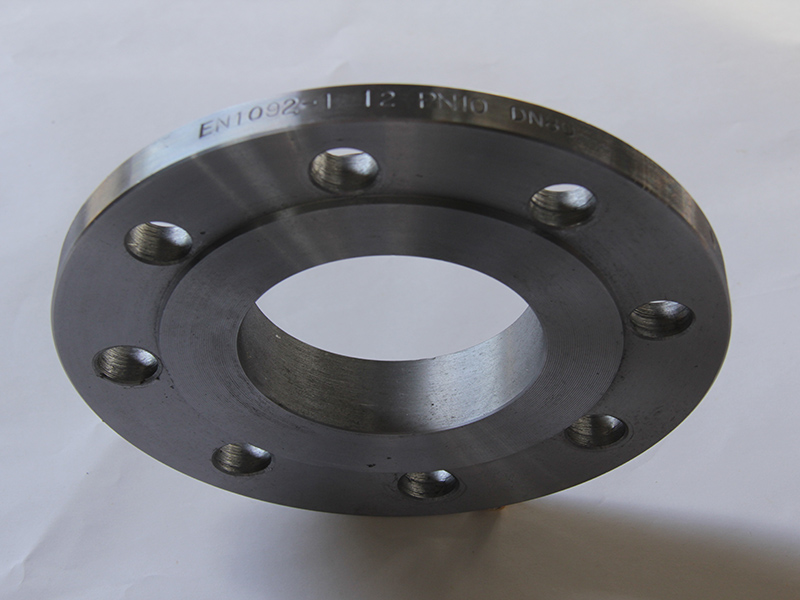

EN1092-1 Flanges

Standard: EN1092-1

Type:Type 01 ;Type 02; Type 05; Type11; Type12; Type13

Flanges Introduction:

A flange is a method of connecting pipes, valves, pumps and other equipment to form a pipework system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or crewed into such systems and then joined with bolts.

Product Specification:

| 1. Standard: | EN1092-1 | |

| 2. Type: | Type 01 ;Type 02; Type 05; Type11; Type12; Type13 | |

| 3. Pressure Class: | PN6;PN10; PN16; PN25; PN40; | |

| 4. Dimension: | DN10-2000 | |

| 5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

| 6. Raw Material: | RST 37.2; P245GH ; S235JR | |

| 7. Packing | Wooden Case, Pallet. | |

| 8. Payment: | L/C, T/T, Western Union, PayPal | |

| 9. Delivery time: | 30 ~60 days after confirm the order | |

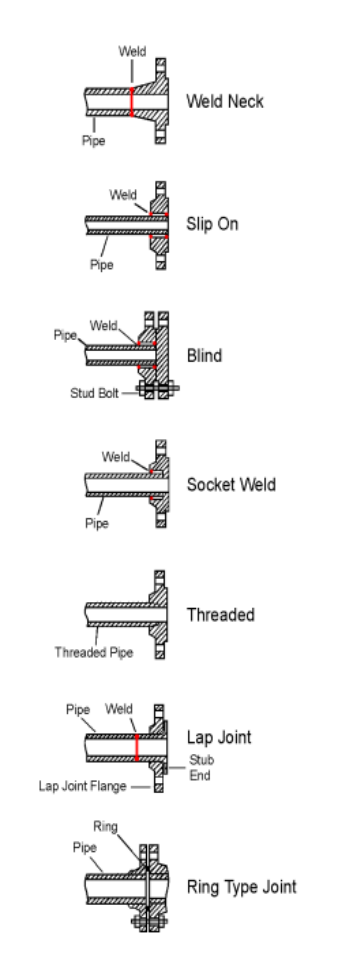

Flange types:

Weld Neck This flange is circumferntially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications. |

|

Slip On This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. | |

Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. | |

Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. | |

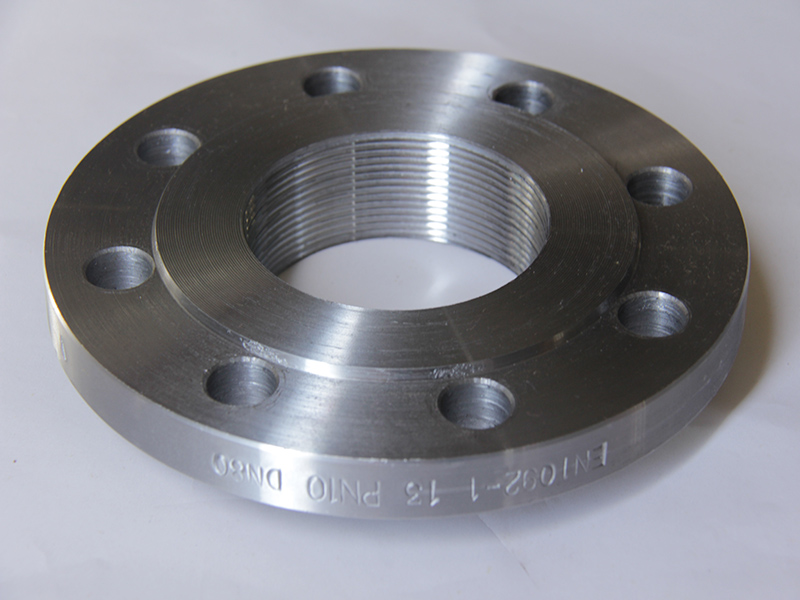

Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. | |

Lap joint This flange is used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost this flanges can be supplied without a hub and/or in treated, coated carbon steel. | |

Ring Type Joint This is a method of ensuring leak proof flange connection and high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Nexk, slip-on and blind flanges. |

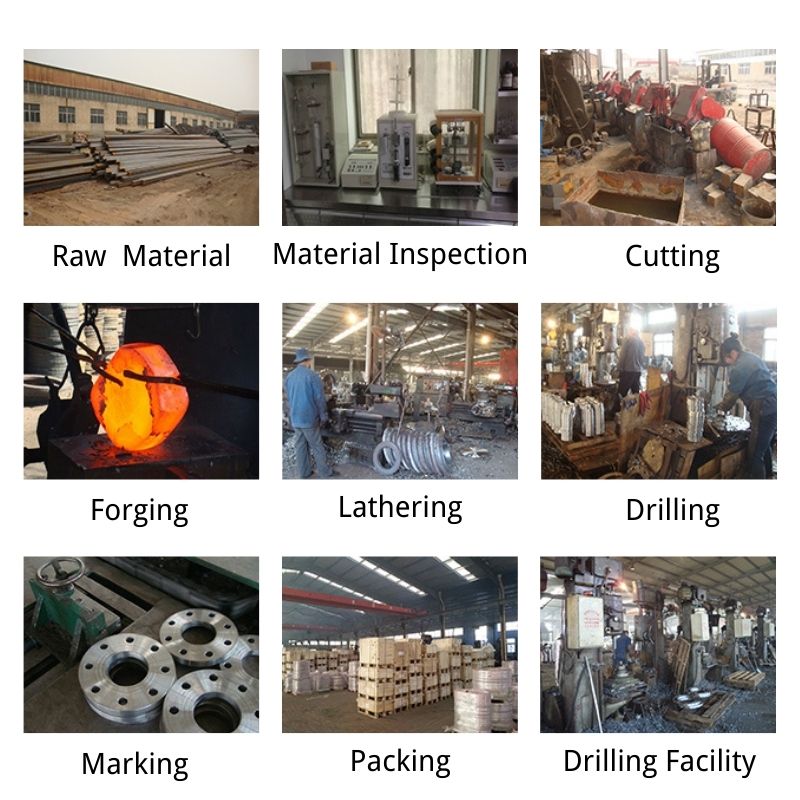

Production Process:

Our group:

Jinan Jiang Hua Forging Machinery Co.,Ltd was established in 1995. The company located in the eastern suburd of Jinan,possesses a favorable position: with Jinan International Airport to its west and Qingdao Port to its east. The company covers 48000 square meters, has 38,000,000,000 RMB investment and possesses 360 staffs and more than 30 technicians. Annual capacity is more than 10000 tons.

We have more than 15 years’s experiences on production and export of all kinds of plate flange,flat flange,slip on flange, welding neck flange,long welding neck flange,blind flange,socket welding flange,threaded flange, screwed flange, lap joint flange. Company produces carbon steel flanges according to the strandard of ANSI/ASME,DIN,JIS,BS,GB,SH. We can also produce Non-standard flanges as per the drawings and samples provided by customers. At present we have acquired ISO9001:2000 Quality System Certificate. Our products are widely used in many key-building engineering in China, and mainly exported to USA,Germany,Canada,Spain,Japan,Middle East,Southeastern Asian countries and regions.

We abide by the permanent goal: Quality-first, honesty-based. We will constantly introduce advanced technology and develop new products to supply excellent ones with higher quality and better service for our clients, We sincerely wish to establish business relationship with all the customers from the world to cooperate with us for better development and brilliant success.

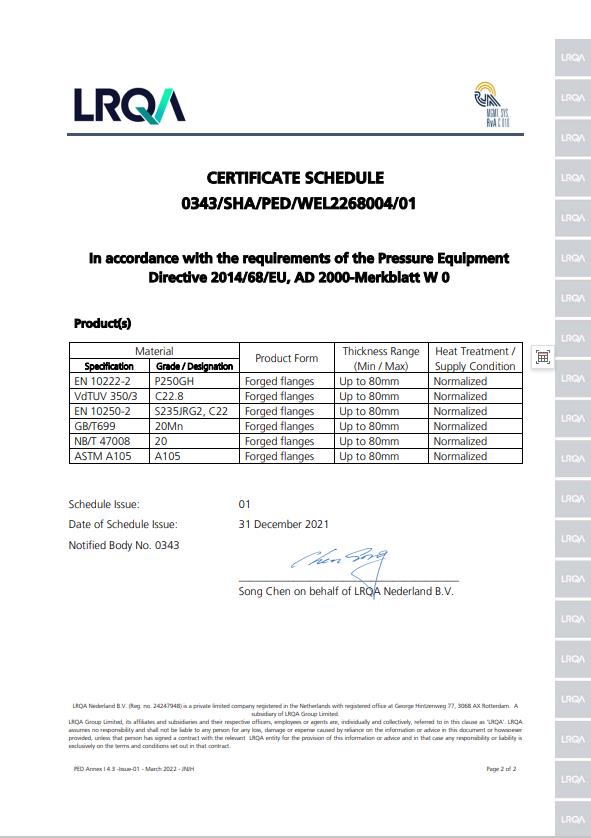

Our Certificates:

| 1. Standard: | EN1092-1 | |

| 2. Type: | Type 01 ;Type 02; Type 05; Type11; Type12; Type13 | |

| 3. Pressure Class: | PN6;PN10; PN16; PN25; PN40; | |

| 4. Dimension: | DN10-2000 | |

| 5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

| 6. Raw Material: | RST 37.2; P245GH ; S235JR | |

| 7. Packing | Wooden Case, Pallet. | |

| 8. Payment: | L/C, T/T, Western Union, PayPal | |

| 9. Delivery time: | 30 ~60 days after confirm the order | |